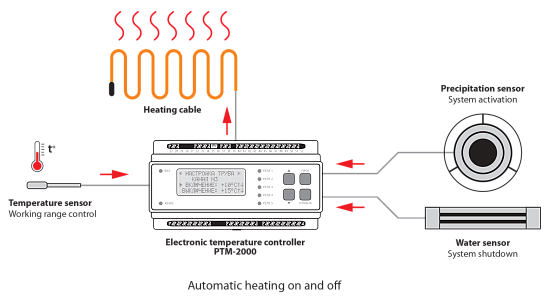

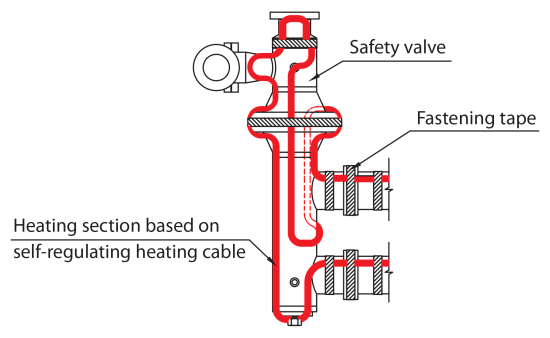

Sigmian has developed solutions based on electric heating cables to significantly improve the operational safety of machinery and equipment in harsh climatic conditions and provide protection against icing of aircraft infrastructure and ships.

- Prevention of icing of ship equipment at temperatures up to −60 °C

- Reliable operation of components and assemblies of aircrafts at low temperatures

- Uninterrupted operation of special equipment and fire systems

- Safe movement of personnel on the evacuation routes of the vessel

- Efficient and autonomous ice removal from helipads for safe landing and take-off of helicopters

- Heaters can be manufactured in different sizes and power outputs

- Our R&D-center designs custom-made solutions for your specific needs