- Heating Cables

- Self-Regulating Heating Cables

- Self-Regulating Heating Cable HTM

- Self-Regulating Heating Cable HTA

- Self-Regulating Heating Cable HTP

- Self-Regulating Heating Cable BTC

- Self-Regulating Heating Cable BTCe

- Self-Regulating Heating Cable BTX

- Self-Regulating Heating Cable BTXe

- Self-Regulating Heating Cable CTE

- Self-Regulating Heating Cable VTM

- Self-Regulating Heating Cable VTL

- Self-Regulating Heating Cable VTR

- Self-Regulating Heating Cable LTM

- Self-Regulating Heating Cable LTL

- Self-Regulating Heating Cable LTR

- Series-Resistance Heating Cables

- Mineral-insulated cables

- Self-Regulating Heating Cables

- Connection Technology

- Junction Boxes

- Explosion Proof Polyester Enclosure

- Junction Box ECO CB

- Junction Box for Heating Cable with Mineral Insulation

- Junction Box for Light Indication

- Junction Box for Power Cables Connection

- Junction Box for Self-Regulating Heating Cables to Power Connection

- Junction Box for Self-Regulating Heating Cables to Power Connection (UVK)

- Junction Box for Series Resistance Heating Cable

- Junction Boxes for Connection of Data, Control and Signal Cables

- Junction Boxes for Connection of Heating Cables with Mineral Insulation

- Junction Boxes for Light Indication and Connection of Heating Cables to Power Supply

- Junction Boxes for Self-Regulating Heating Cables

- Junction Boxes for Self-Regulating Heating Cables (3 and More Circuits)

- Junction Boxes for Series-Resistance Cables

- Junction Boxes for Three-Phase Series-Resistance Heating Cables Connection

- Cable Glands

- Connection Kits & Accessories

- Junction Boxes

- Commercial De-icing Systems

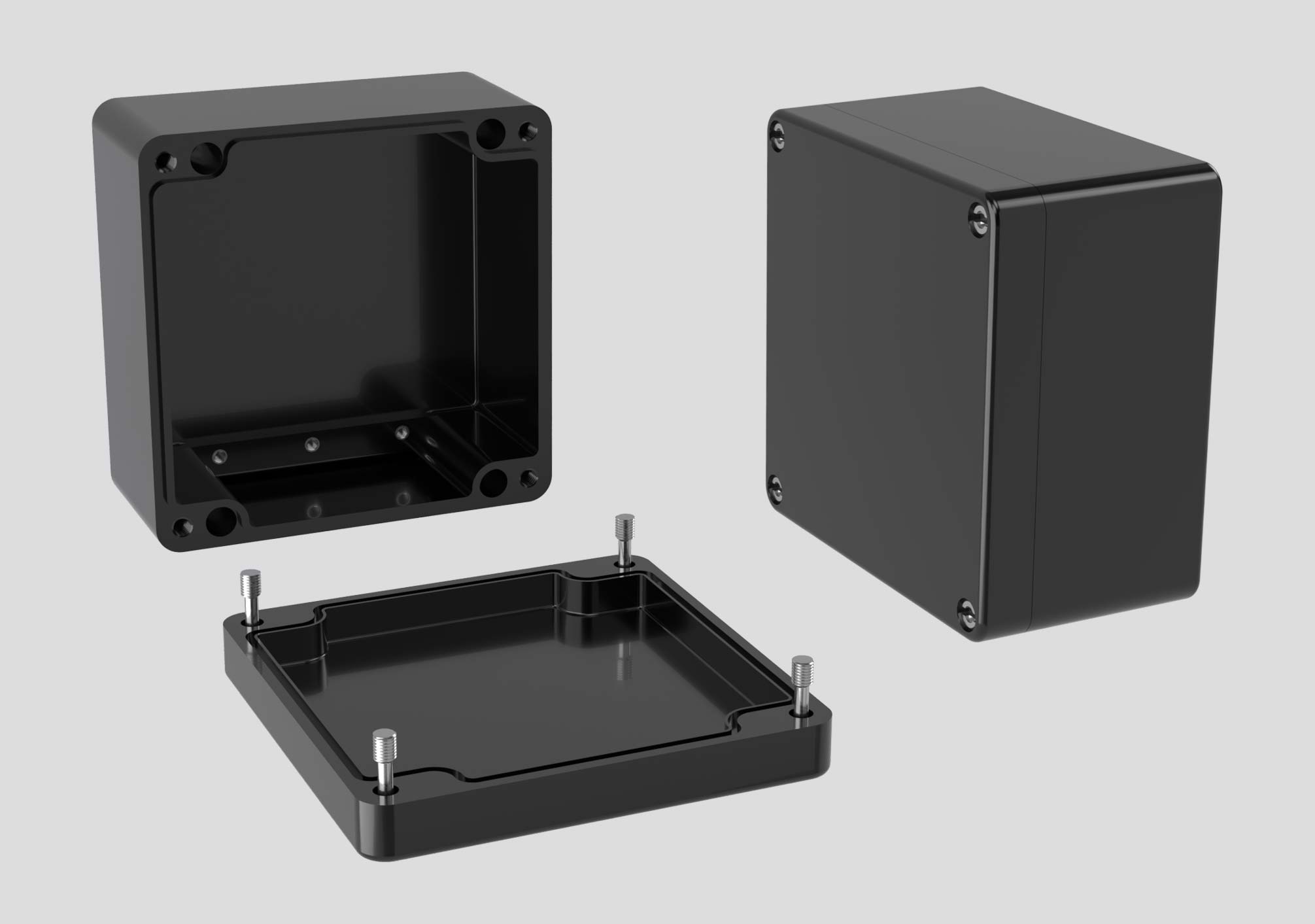

Explosion Proof Polyester Enclosure

Application Areas

- Control stations

- Automatic circuit breakers

- Control devices

- Electrical enclosures

- Switches and changeover switches

- Distribution boxes

- Alarm devices

- Instrument enclosures

- Battery containers

Approvals

Glass reinforced polyester enclosures are used at chemical and petrochemical factories, on offshore platforms, oilprocessing plants and at other branches with potential availability of hazardous atmosphere (gas and combustible dust).

A wide range of models is intended for installation of electrical components and automation equipment, could be mounted indoor or outdoor in explosion hazardous zones, where explosive environment occurrence is possible.

Enclosures consist of a case and a lid fixed with captive loosing resistant screws. Enclosures are made of polyester reinforced with fiberglass, providing maximum protection from highly corrosive agents.

Graphite black color gives the maximum protection from UV radiation. Chemical composition of enclosure material eliminates any risks from sources of ignition by the means of statically induced sparking resistance. Enclosure sealing system has the shape of labyrinth, where silicone sealing is protected from environmental factors impact. Due to this quality, enclosures have a high ingress protection performance — IP66.

Inside enclosures there following electrical components could be installed: mounting panel, DIN-rails with terminals, earthing busbar and others. On the sides of boxes there could be installed explosion proof cable glands for different cable types, couplings, plugs, valves, earthing tags, etc.

In SST Group of Companies these enclosure types are used for the production of explosion proof equipment with “Equipment protection by increased safety” — “е” level; “Equipment dust ignition protection” — “t” level.

| Climatic version and location category according to GOST 15150-69 | F1, NF1 (NF4, NF5, Т1, Т2, Т3, Т5, F5, MU1, MU2, MU3, MU4, W5 – upon requirement) |

|---|---|

| Ingress protection | IP66 |

| Operating ambient temperature range | −60 ... +55 °С |

| Impact resistance | IK08 / 7J |